|

|

|

|

|

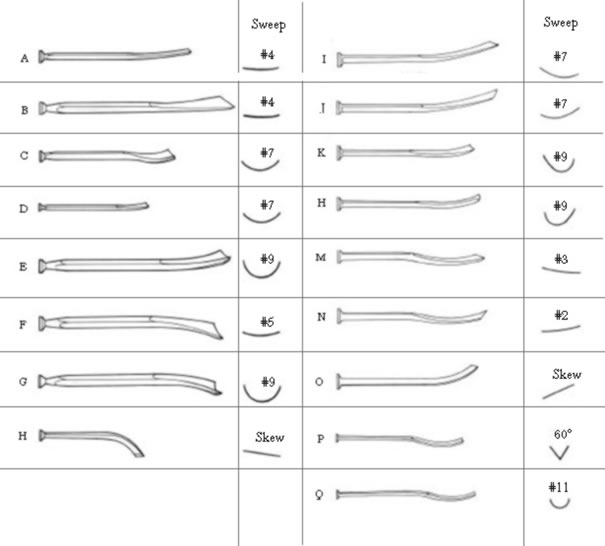

| A Guide to Coglow Skew Gouges |

posted on 11:28am by David |

|

|

A guide to selecting, using, sharpening and honing Coglow Skew Gouges.

Introduction

Woodcarving is a traditional art and craft which has seen a considerable body of fine work produced with instruments which have changed little over the past three centuries, and in many cases, over the past millennium. If those implements proved adequate for so long, it seems at the very least redundant and quite probably audacious to introduce new concepts and striking alterations to those customary tools.

I am inclined to think otherwise. The only given is that the improvements must be genuine and the article of highest quality. A number of events in my own carving career led to the conviction that chisel modification could improve performance in a variety of situations without decreasing their utility in others. To begin with, there were the periodic instances when my traditional tools. some 400 in number, were not entirely adequate to the demands. Another consideration was the simple observation that certain tool bends were much more functional suited to the dynamics of human physiology than others, which led to the belief that most might be further improved. To this was added the premise that, if the skewed angle of the guillotine decreased resistance and improved efficacy, the same might be accomplished for a gouge by skewing the blade. Knowledge of the workings of a properly sharpened venier (Figure 1) blade made it equally apparent that a skewed gouge would possess advantages in carving against the grain.

The properly sharpened veiner has extended wings and a recessed trough, making it possible for the wing which it fighting the grain to sever the opposing fibers in advance of the trough. It logically followed that a skewed gouge could present a more radically extended wing than a veiner and allow it to cut smoothly while working in an even more pronounced opposition to the grain. This would alleviate much of the need to change direction of attack and the concomitant necessity of the carver to reposition either or both himself and the work progress. Furthermore, skewing of the gouges would impart this same advantage of properly sharpened veiners to the shallower gouges with their lesser sweeps.

FIGURE 1 - A Veiner properly sharpened, showing recessed trough.

General Characteristics

1. Ergonomically Designed. Each of these tools is designed to present the cutting edge to a particular set of contours in such a fashion as to be conducive to a smooth and effective economy of motion. The act of paring with a chisel is not dissimilar from the use of a bat or club in sports, where much of the satisfaction and success is dependent upon the proper motion of presentation and follow-through.

2. Natural or Positive Rotation (Figure 2). Many carvers apply a slight lateral rotation in using their gouges to produce a smoother cutting action. While the skew motion to the gouges accomplishes this same purpose of itself, it also lends to a rotational proclivity which enhances as the sweep to the gouge increases. While the practice is generally to apply the minimal effort required to control or reverse the natural rotation, there are times when the natural rotation is encouraged or exaggerated for its particular cutting action or simply to extricate a gouge from an excessive bite without stopping the cut and retreating.

|

|

FIGURE 2 - Positive rotation; as the skew is pushed forward it will tend to rotate in the direction of the point. clockwise In this case. This tendency can be exaggerated for a smooth combination cutting action, stopped or reversed or the situation demand. |

3. Lateral Cuts/Reverse Rotation. (Figure 3) Any shallow gouge can be forced sideways. but its blade requires that both forward and lateral pressure be applied. A skew-gouge, by virtue of the extended wing. presents a cutting edge which works with only laterally applied pressure. This works to the carver's advantage in a number of situations. especially in coping with the demands of the rapidly reversing fiber direction in complex grain patterns and the "rolling-over" of certain contours.

With the greater sweeps, this lateral motion in the direction of the skew's heel becomes reverse rotation, and works well to sever an accumulation of fibers at the base of a protected area to leave the skew-gouge's cut with a squared or gently rounded terminus (depending on shank adjustments during rotation), or to facilitate smooth cutting action when cutting diagonally against the grain.

|

|

FIGURE 3 - Any shallow gouge can be forced sideways, but with a skew-gouge the effort is much easier. This expanded range of motion can at times be used to allow a substantial cut near a fragile extension without breaking it, to permit a particular texturing motion. or simply to use the most economical motion for a desired task. Its chief advantage, however, is often that it expedites work in irregular grain with the increased ease of shifting direction of cut. |

4. The advantages of a properly sharpened veiner gouge without the principle disadvantage as designed, the wing of the skew allows the carver to work in opposition to the grain as one might with a veiner gouge. A properly sharpened veiner gouge. however. suffers from the problem that one wing can be doing damage while the other is making the desired cut or its cut may have to be stopped short in order to prevent both wings from damaging a protected area rising from the far side of a recess. Here again. the control and reverse rotational abilities of the skew-gouge allows a finished cut without causing harm to the protected areas. (It should be noted that a cut in opposition to the grain will not always be a finished cut. Depending on the wood, the angle of attack and the set of the skew, there may be some tearing where the opposing grain meets the "valley".

5. Skew-gouges decrease the wood's resistance. More precisely. they take advantage of Its physical properties Most carvers realize that. when working the face grain, the path of least resistance is to cut across the grain, severing both "anchoring" ends of individual fibers simultaneously. With the right and left skew, the opportunities for so working are significantly increased. and logically dictates as a rule of thumb that one employs that skew-gouge which presents its blade more parallel to the fiber direction.

Exception to the rule is the instance in which only one end of the fibers need severing, in which case large amounts of stock can rapidly be removed by presenting the skewed gouge perpendicular to fiber direction and employing only the heel, causing stock to split away as the fiber "anchors" are severed.

6. The pointed blade is often convenient of itself. It allows certain knifing actions and has greater accessibility to those sharp recesses, yet can duplicate the same cuts as a standard gouge.

7. Extra Length. A number of these tools have extended shanks which are fairly heavy. Their purpose is to provide increased accessibility and extra grip, hence control, for the guiding hand.

The Individual Tools

For the sake of brevity, I will resist the urge to expound on specific applications of the individual tools, save the one which is not a gouge. i.e., the bent or incising skews. These odd looking instruments are generally used for a variety of kniving actions. They are superior to a knife in establishing Incisions, especially when the cut is not quite parallel to the line of the fiber. In such cases, a knife is prone to catch in the grain and wander, but the bent skew is adroitly held in complete control, whether pushing and incising with the heel or pulling and cutting with the point. It also works exceptionally well in detailing and cleaning along sharp demarcations such as the edge of a seam.

It can be used gliding on its "elbow" to establish sharp V-cuts in end-grain, but more often the elbow is used as a fulcrum, and a very effective one, against the fingers in a knifing or whittling action. The advantage here Is not only power, but considerably greater control and accessibility. It is a tool which I have come to use extensively.

As to the other tools. their specific applications are numerous and varied. Logic and experimentation should readily reveal their individual talents, providing they are properly sharpened and that can not be stressed too much.

Comments:

A singular advantage to these tools when used for rough-out is that they can easily and cleanly remove the accumulation of chaff at the bottom of a recess or base of a protected area simply by raising the shaft and applying reverse rotation. The same can be done with some standard short-bent gouges, but it is more deftly accomplished with the skews.

FIGURE 4 - The profile of a back-bent skew gouge (solid line) versus that of a standard back-bent "X" indicates the greater clearance which translates to greater versatility and comfort. Ability to cut on the face side is the same, save that the skew has a lesser resistance. |

The Back Bents:

These were designed to facilitate the execution of folds. particularly as they wrap about a convex form and frequently call for working in acute opposition to the grain. They are also proficient rough-out, profiling, and end-grain tools.

Beyond its skew, the advantage of this back bent over the conventional models is that it does not have an elbow to limit the size and shape of contours it can handle, and that, in paring situations, it allows extra clearance for the fingers of the hand gripping the shank (see Figure 4).

Sharpening

As with any chisel, proper sharpening is of utmost importance. The recommended degree of skew ranges from 17.5° for the spoon models to 22.5° for most back-bents to 27.5° for the #4 sweeps. It is important to note that the skew angle for the back-bents should be examined from a point perpendicular to the plane of the top of the blade at its end (see Figure 5), rather than from a point perpendicular to the shaft, and also from the profile of the wing. A skew may be seen from other perspectives. but it will not necessarily be a functional skew. A slightly rounded bevel is recommended. with just a hint of a bevel applied to the inside edge, so that the bevel at the cutting point is 20°-25° and quickly works down to 15°-17°. There should be no abrupt heel to the bevel; rather the bevel should merge with the contour of the bend. beyond that, users are advised to round any face of the tool which will not have an eventual bearing on the blade. This is simply a precaution to reduce marring caused by the back or shank of the chisel.

|

|

FIGURE 5 - When examining the back-bent skew-gouges for the proper skew, they should be viewed from above at a point perpendicular to the blade and double checked from the profile on the point side. Note: because of the curvature of the sweep, the profile skew will not be as great as the skew viewed from the top. Both may be set to individual preference. |

Note:

The majority of the skew-gouges' work should be done with the trough and heel of the blade. The point can be buried so long as the carver is careful to continue with a cutting rather than a prying action. I have yet to break a point. but would recommend that users maintain their blades with a slightly greater bevel towards the point while decreasing it towards the heel of the skew.

My paring work exceeds my mallet use by perhaps a 4:1 or greater ratio with these tools as with my other chisels. The skew gouges do work well with a mallet, though the shallower sweeps have a pronounced tendency to wander in the direction of the point. This easily controlled by barely catching the point of the blade in the wood.

We are indebted to Fred Cogelow for the above observations.

All Cogelow gouges are fitted with octagon shaped Beach Wood Handles

|

|

|

|

|

|

|

|

Click Here to View Catalog

Click Here to View Catalog