|

|

|

|

|

|

|

|

| The Care and Sharpening of Single Bevel Japanese Kitchen Knives |

posted on 11:41am by David |

|

Special sharpening techniques for Japanese kitchen knives. (Hocho)

Introduction

Thank you for purchasing one of our fine quality, single bevel Japanese kitchen knives. The Kanji characters for Hocho are a synonym for "symbol of wealth". The Hocho is an important part of Japanese culture and is highly valued as a gift item for weddings and other important social events.

All of our Hocho are hand-forged by master knife makers. Special, expensive forging techniques known as "Hon Kasumi" and "Hon Yaki" ensure our Hocho will take and hold an edge impossible to obtain with any Western made knife. With care in handling and sharpening, the cutting qualities of your Hocho will continue to improve over the years.

A well sharpened edge is a delicate thing. Always use a cutting board. (We prefer soft plastic types, as they are considerably more hygienic and easier on the edge than are wooden boards.) Be sure never to strike the edge against a hard surface such as counter tops, metal objects or glassware, etc. Never use the blade as a pry bar or can opener and refrain from sending your knife through the dishwasher.

The Sashimi and Usuba shapes should never be used to cut bones or vegetables with a hard rind such as winter squash. They should only be used for slicing, never for cleaving.

The Deba shape can be used to cut uncooked chicken and fish bones. The proper way to cut bone is to place the knife on the spot where the cut is to be made and then strike the top edge of the blade with the palm of the left hand, while at the same time applying downward pressure on the handle with the right hand.

After use, always rinse the blade in warm water and wipe dry. Apply a bit of camellia oil to the blade and store in a dry, well protected place. A wooden sheath is well worth the investment to protect the edge during storage. Wooden sheaths are relatively easy to build and make an interesting afternoon's project.

Initial Care

While all of our new Hocho are ready for use, the following two steps will enhance its beauty and increase its longevity. First, soak the handle for twenty minutes in a tung oil finish. (Non-toxic Sealacell Oil Finish is highly recommended.) Be sure to totally submerge the handle. Remove the handle from the finish and completely wipe dry with a soft cloth. Allow the handle to dry overnight before subjecting it to water. The second step is performed over a period of 30 days. Each day rub down the blade with a bit of scouring powder such as that used to clean the bottom of copper pots. Be sure to keep your fingers well clear of the edge. This procedure refines and polishes the surface of the blade. A well polished blade is much less likely to develop tarnish or rust.

Sharpening

Sharpening a single bevel Hocho is relatively easy. The first step is to obtain several water stones, a coarse #1000 grit stone and a fine #4000 or #6000 grit stone. After submerging the #1000 grit stone in a container of water for several minutes, flatten it by rubbing back and forth on a sheet of #220 grit wet/dry sandpaper placed on a flat surface such as a counter top. It will be obvious by inspection when the stone surface is flat.

Next, place the blade with hollow side flat on the #1000 grit stone. The blade should be held at an angle of about 30 degrees to the length of the stone. Now rub the blade back and forth on the stone, while at the same time moving the blade across the width of the stone. With long blades, it will be necessary to sharpen the blade a section at a time. Be sure to overlap each section. Continue in this manner until the entire blade as been rubbed on the stone. Occasionally inspect the blade to be sure all parts along the edge are being flattened. PLEASE NOTE: It is only necessary to have a very small area (about 1/32") directly behind the edge flattened. Continue rubbing on the #1000 grit stone until this area behind the edge is flattened along the full length of the blade.

Now turn the blade over and sharpen the bevel side. Hold the blade at an angle of about 30 degrees to the length of the stone. Rub up and down the stone while at the same time moving the blade across the width of the stone. As above with long blades, it will be necessary to sharpen a section at a time. Be sure to keep the bevel flat on the stone while sharpening. Continue in this manner until a wire edge is detected along the full length of the blade.

Now transfer the blade to the fine grit stone, and alternately rub back and bevel sides as described above until both are well polished and the wire edge is removed. Finally, tip the bevel side up approximately 5 degrees and hone for six or seven strokes on the bevel side. Reverse the blade and again hone the back side flat on the stone for an equal number of strokes. This step creates a micro-bevel which toughens the edge without harming its cutting effect.

The life of the edge can be considerably extended between sharpenings by stropping once a week with a fine aluminum oxide abrasive. Always strop the bevel side of the blade at the angle of the micro-bevel. This is typically about 5 degrees. Be sure to keep the back side of the blade flat against the strop. When stropping, always draw the blade with the edge trailing. Otherwise, the blade would slice into the strop.

The purchaser should feel free at any time to contact us with any questions regarding the care and use of their Hocho.

Supplies

If not obtainable locally, Camilia oil, Sealacell non-toxic finishes, Strop and Abrasive can be obtained from The Japan Woodworker. The Japan Woodworker has the largest selection of water stones available to suit any sharpening situation. If you are undecided as to which stones to select, please feel free to call us for our recommendation.

Comments (3)

|

|

|

|

|

|

|

|

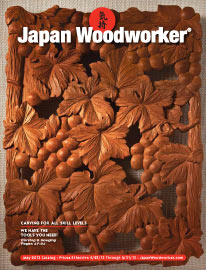

Click Here to View Catalog

Click Here to View Catalog